Download Our Latest Product Catalog

Elevator Cables and Wire Ropes

- Hoist ropes — 8x19 Classification, Liftpac™, Syncor

- Governor ropes — 6x19 and 8x19 Classification

- Compensating ropes — 6x19 and 8x19 Classification

Standard Elevator Rope

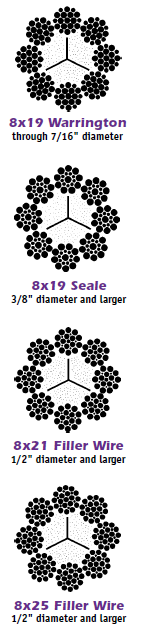

Hoist Ropes

With the advent of high rise elevators and increased car speeds, elevator designers and manufacturers frequently select a higher strength hoist rope. The grade of steel (traction, extra high strength traction) is dependent upon many factors, the most critical being load requirement and car speed. It is not always advantageous to use an EHS traction rope where traction will suffice. The low carbon wire used on traction grade wire ropes may provide better fatigue life than a higher carbon EHS wire.

Drum and Counterweight Ropes

Use 8x19 Seale traction steel ropes for most drum and counterweight ropes. If the drum and sheave material of the existing elevator is softer than that required for traction steel, the use of iron ropes may be considered.

Compensating Ropes

8x25 Filler Wire traction steel ropes provide longer and more economical service. For existing installations that require iron, WW suggests 8x25 Filler Wire.

Governor Ropes

Use an 8-strand traction steel governor rope for longer service life, unless iron is specified. Make sure replacement governor ropes are in accordance with the elevator manufacturer's specifications.

Elevator Hoist Rope with Steel Core (IWRC)

Steel Core elevator hoist ropes are used where additional strength is required without increasing the diameter of the wire rope. An additional benefit of the steel core is that these ropes will exhibit somewhat reduced stretch when compared with that of fiber core ropes. Equipment utilizing Steel Core hoist ropes are specifically designed with steel core ropes in mind and are not to have fiber core ropes substituted.

Lift-Pac

Lift-Pac is designed for use wherever elevator hoist ropes exhibit short service life due to adverse operating conditions. Primary applications include:

- systems with reverse bends

- applications where wire fatigue breakage with minimal surface wear is the cause for retirement

- where high groove pressures cause uneven and accelerated wear.

Lift-Pac is not recommended for high rise/high speed applications. Also, Lift-Pac should not be used as a remedy for poor rope performance due to worn sheaves and/or differential groove depths.