Download Our Latest Product Catalog

General Purpose Wire Ropes

- Standard wire ropes - 6x7, 6x19, and 6x37 Classifications

- Spin-resistant - 8x19 Class, 19x7, SFP 19™ and SFP 35™

- Specialized wire ropes Flattened Strand, 6-Pac™, 6-Pac RV™

- Super-B™, Super-Pac™, Triple-Pac™

- Plastic-infused - BXL™, 6-Pac BXL

Standard Wire Ropes

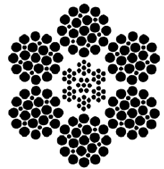

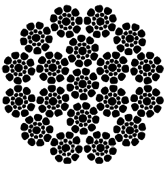

6x7 Class Wire Rope

Strands: 6

Wires per strand: 7

Core: Fiber core

Standard grade(s): Purple

Lay: Regular or Lang

Finish: Bright or galvanized

This construction is used where ropes are dragged on the ground or over rollers, and resistance to wear and abrasion are important factors. The wires are quite large and will stand a great deal of wear. In fact, this construction is sometimes called “coarse laid” because of the large wires. The 6x7 is a stiff rope and needs sheaves and drums of large size. It will not withstand bending stresses as well as ropes with smaller wires. Because of the small number of wires, with the resulting higher percentage of load carried by each wire, a larger factor of safety should be considered with 6x7 ropes than with ropes having a larger number of wires.

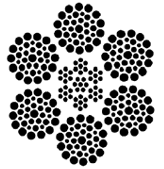

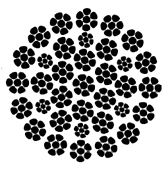

6x19 Class Wire Rope

Strands: 6

Wires per strand: 19 to 26

Core: IWRC or fiber core

Standard Grade: Purple Plus

Lay: Regular or Lang

Finish: Bright or galvanized

The 6x19 Classification of wire rope is the most widely used. With its good combination of flexibility and wear resistance, rope in this class can be suited to the specific needs of diverse kinds of machinery and equipment. The 6x19 Seale construction, with its large outer wires, provides great ruggedness and resistance to abrasion and crushing. However, its resistance to fatigue is somewhat less than that offered by a 6x25 construction. The 6x25 possesses the best combination of flexibility and wear resistance in the 6x19 Class due to the filler wires providing support and imparting stability to the strand. The 6x26 Warrington Seale construction has a high resistance to crushing. This construction is a good choice where the end user needs the wear resistance of a 6x19 Class Rope and the flexibility midway between a 6x19 Class and 6x37 Class rope.

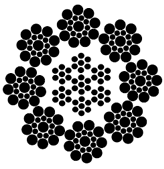

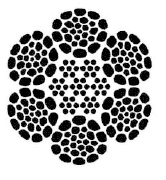

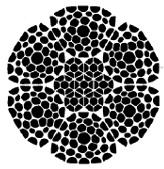

6x36 Class Wire Rope

Strands: 6

Wires per strand: 27 to 49

Core: IWRC or fiber core

Standard Grade: Purple Plus

Lay: Regular or Lang

Finish: Bright or galvanized

The 6x36 Class of wire rope is characterized by the relatively large number of wires used in each strand. Ropes of this class are among the most flexible available due to the greater number of wires per strand, however their resistance to abrasion is less than ropes in the 6x19 Class. The designation 6x36 is only nominal, as in the case with the 6x19 Class. Improvements in wire rope design, as well as changing machine designs, have resulted in the use of strands with widely varying numbers of wires and a smaller number of available constructions. Typical 6x37 Class constructions include 6x33 for diameters under 1/2", 6x36 Warrington Seale (the most common 6x37 Class construction) offered in diameters 1/2" through 1-5/8", and 6x49 Filler Wire Seale over 1-3/4" diameter.

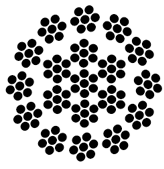

Alternate Lay Wire Rope

Strands: 6

Wires per strand: 26

Core: IWRC

Standard Grade: Purple Plus

Lay: Combination

Finish: Bright

Alternate Lay, sometimes referred to as reverse lay, is a stranded rope where the type of lay of the outer strands is alternately regular lay followed by lang lay such that three of the outer strands are regular lay and three are lang lay. Alternate lay wire rope has the extra flexibility of lang lay in combination with the structural stability of regular lay. It unites the best features of both types of wire rope. Alternate lay is made with relatively large outer wires to provide increase of abrasion resistance to scrubbing against sheaves and drums. Finer inside wires and flexibility enable alternate lay ropes to absorb severe bending stresses. It is well suited to winding applications where abrasion and crushing can occur. Alternate lay wire rope applications include boom hoists and numerous types of excavating equipment like clamshells, shovels, cranes, winches and scrapers.

Spin-Resistant / Rotation-Resistant Wire Ropes

8x19 Classification

Rotation-Resistant

Strands: 8

Wires per strand: 19 to 25

Core: IWRC

Standard grade(s): Purple Plus

Lay: Right Regular

Finish: Bright

The 8x19 Classification rotation resistant ropes are recommended for hoisting unguided loads with a single-part or multipart line. The eight outer strands are manufactured in right lay, with the inner strands being left lay. These ropes are slightly stronger and significantly more rugged than the 19x7 construction. However, the rotation-resistant properties of the 8x19 rotation-resistant ropes are much less than those of the 19x7 construction. These ropes are manufactured in right regular lay in the 8x19 Seale and 8x25 Filler Wire constructions.

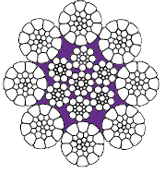

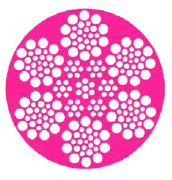

19x7 Rotation-Resistant

Strands: 19

Wires per strand: 7

Core: WSC

Standard grade(s): Purple Plus

Lay: Regular

Finish: Bright

19x7 is recommended for hoisting unguided loads with a single-part line. The rotation-resistant properties of this rope are secured by two layers of strands. The inner strands are left lay, while the 12 outer strands are right lay, which enables one layer to counteract the other layer's rotation. The rotation-resistant characteristics of the 19x7 wire ropes are superior to those of the 8x19 Class wire ropes.

Super Flex Pac 19

Strands: 19

Wires per strand: 7/19

Core: WSC

Standard grade(s): Royal Purple

Lay: Right Regular

Finish: Bright

SFP 19 is recommended for both multipart load and single-part fast line applications where rotational stability of the lifted load is needed, such as for use as a long fall on offshore pedestal cranes, rough and all terrain cranes, and crawler cranes. SFP 19 provides:

Fatigue Resistance. Improved fatigue properties are derived through the combination of the flexible 19x19 construction and die drawn strands. The drawn strand surfaces minimize the interstrand and interlayer nicking that take place in round rotation resistant ropes.

Abrasion Resistance. Die drawn ropes provide improved abrasion resistance as compared with round wire ropes because of the greater wire and strand bearing surfaces contacting sheaves and drums.

Resistance to Drum Crushing. SFP 19 wire ropes are resistant to the effects of drum crushing due to the compacted strands and smoothness of the rope surface.

Super Flex Pac 35

Strands: 35

Wires per strand: 7

Core: WSC

Standard grade(s): 2160 N/mm2

Lay: Right Regular

Finish: Bright

SFP 35 is a rotation-resistant rope of high strength that can resist block twist in long falls. SFP 35 provides:

Superior Rotation Resistance. The SFP 35 rope is the most rotation resistant rope manufactured by WW. Due to its rotation resistant properties, SFP 35 may be used with a swivel in both single part and multipart reeving.

High Strength. WW's compaction process provides a high strength rope which exceeds EEIP nominal breaking strength.

Application. SFP 35 excels in crawler and truck-type crane load lines, and tower crane hoist ropes.

Flexibility. SFP 35's multiple strand construction provides increased flexibility which improves service life and high speed spooling. The compacted compacted multiple strand construction also reduces sheave and drum abrasion and provides excellent resistance to drum crushing.

Specialized Wire Rope

6-PAC

Strands: 6

Wires per strand: 19 to 36

Core: IWRC

Standard grade(s): Royal Purple

Lay: Right Regular

Finish: Bright

6-PAC is recommended for use where the rope is subjected to heavy use or where conditions are extremely abusive, such as offshore pedestal, crawler and lattice boom equipped truck crane boom hoist applications. 6-PAC is also recommended for winch lines, overhead cranes, multipart hoist lines where rotation-resistant ropes are not required, and other applications where flexibility, high strength and resistance to crushing are important, and a cost-effective 6-strand rope is desired.

6-PAC provides:

Fatigue Resistance. Improved fatigue properties are derived from the combination of 6-PAC's flexible constructions and the compacted strands. The compacted strand surface minimizes the interstrand and interlayer nicking that take place in standard 6-strand ropes.

Abrasion Resistance. 6-PAC's compacted strand design provides improved abrasion resistance as compared to standard 6-strand ropes because of the increased wire and strand surfaces contacting sheaves and drums.

Flexibility. 6-PAC's design provides increased flexibility, making it easy to install, and 6-PAC also offers better spooling at high line speeds.

Resistance to multilayer.

Drum Crushing. 6-PAC dramatically increases the amount of wire contact with the drums and sheaves, reducing the wire rope, sheave and drum wear normally associated with standard wire rope.

Damage at the crossover points is also reduced.

SUPER-B Swaged

- Recommended for applications where abrasion and fatigue resistance is required, such as for winch lines, chokers, skylines, and haul backs, as well as any application where a swaged rope is used

- Manufactured right regular lay in a 6x26 construction

- Provides excellent resistance to abrasion and multilayer drum crushing

- OffersEEIP+ breaking strength

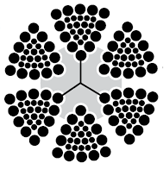

8-PAC

Strands: 8

Wires per strand: 19 to 36

Core: Plastic filled (BXL)

Standard grade(s): Royal Purple

Lay: Right

Finish: Bright

8-PAC is recommended for hoist ropes for steel mill ladle cranes and hoist and trolley ropes for container cranes, or other hoisting applications with heavy duty cycles or where severe bending occurs.

Other features of 8-PAC include:

Superior Performance. 8-PAC has higher breaking strength and gives superior performance in difficult hoisting applications compared to standard 6-strand and 6-strand compacted ropes.

Abrasion Resistance. 8-PAC compacted strand design provides improved abrasion resistance as compared to standard 6 and 8 strand ropes because of the increased wire and strand surfaces contacting the sheaves and drums.

Superior Flexibility. 8-PAC is significantly more flexible than standard 6 and compacted 6 strand ropes with better spooling and longer service life.

Resistance to multilayer.

Drum Crushing. 8-PAC's plasticfilled (BXL) core offers increased resistance to crushing through better support of the outer strands.

SUPER-PAC

Strands: 6

Wires per strand: 26/31

Core: IWRC

Standard grade(s): Royal Purple Plus

Lay: Right Regular

Finish: Bright

SUPER-PAC is a double compacted product ideal for applications where abrasion and drum crushing are an issue. When compared with standard ropes, SUPER-PAC provides: Better resistance to multi-layer drum crushing. SUPERPAC dramatically reduces the damage at cross over points on smooth face drums, such as those found on many boom hoist systems on mobile cranes. This is achieved by compaction of the strands and the rope, making a tough but flexible product.

Abrasion Resistance. The compaction process also increases the contact between the rope and the drum and sheaves, reducing sheave and drum wear.

Super Strength. The double compaction process also increases the minimum breaking strength of standard EIP rope more than 20%.

Superior Fatigue Resistance. SUPER-PAC is engineered for overall performance, its wire tensile strength being the key to its superior fatigue resistant properties. In addition to contribution to SUPERPAC’s EEEIP breaking strength, the wire used in the manufacture of SUPER-PAC remains ductile, minimizing the occurrences of external and internal wire breaks caused by operating stresses.

Application. SUPER-PAC is ideal for all types of boom hoist and lowering ropes.

TRIPLE-PAC

Strands: 6

Wires per strand: 26/31 or 36

Core: IWRC

Standard grade(s): Royal Purple Plus

Lay: Right Regular

TRIPLE-PAC was developed for the most demanding hoist applications. TRIPLE-PAC offers the extra high strength and crushing resistance needed for applications such as boom hoist ropes, boom pendants and multipart load lines.

TRIPLE-PAC provides superior abrasion and fatigue resistance as compared with most compacted ropes due to WW’s unique design of compacting the IWRC, individual strands and the rope itself. Other benefits include:

High Strength. TRIPLE-PAC is designed to provide a nominal strength of 35% above EIP. WW achieves this strength through selected grades of steel and TRIPLEPAC’s unique design and manufacturing processes.

Superior Resistance to Multilayer Drum Crushing. TRIPLE-PAC provides superior resistance to crushing through its design. Its triple compaction provides a denser cross section, enabling the rope to withstand the rigors of multilayer spooling. Damage at the cross over points is also significantly reduced.

In addition, TRIPLE-PAC’s design increases the amount of wire contact with sheaves and drums, reducing wire rope, drum and sheave wear.

BXL

Strands: 6

Wires per strand: 19 to 36

Core: IWRC

Standard grade(s): Purple Plus

Lay: Regular or Lang

Finish: Plastic-infused

BXL is infused with a specially- engineered polymer, creating a well-balanced matrix. BXL is recommended for numerous hoist, marine and logging rope applications. BXL provides: Fatigue Resistance. Improved fatigue resistance is derived from the cushioning and dampening effect of the polymer on the wires and strands. BXL also evenly distributes stresses which may lead to fatigue breaks.

Abrasion Resistance. The polymer acts as a barrier between the individual strands, preventing penetration of any adverse material. BXL distributes and reduces contact stresses between the rope and sheave, reducing wire rope wear.

Resistance to multilayer.

Drum Crushing. BXL’s smooth profile evenly distributes crushing pressures from the overlying layers of rope in multilayer drum winding applications.

Extended sheave and drum.

Service Life. BXL minimizes corrugation and wear normally associated with standard rope usage by restricting water and dirt penetration and eliminating pickup of abrasive materials.

Clean Handling. The exterior rope surface is free from the grease normally applied to standard ropes.

SKYBRITE

- Recommended solely for choker ropers used in helicopter logging operations

- Manufactured right regular lay in a 6x26 IWRC construction in EIP grade

- Fluorescent pink for high visibility

FLATTENED STRAND

Strand: 6

Wires per strand: 27

Core: IWRC or fiber core

Standard Grade(s): Purple Plus

Lay: Lang

Finish: Bright

This rope is particularly suitable where severe conditions of crushing and abrasion are encountered on the drum or where a higher strength design factor is required than can be obtained with a similar round rope.

The triangular strand shape not only provides better resistance to crushing, but also offers a greater exposed surface area for contact with sheaves, drums or underlying layers of spooled rope. This feature, in connection with the use of Lang lay construction, distributes the abrasive wear over a greater number and length of wires. The smooth surface of the rope also helps minimize wear on drums and sheaves.

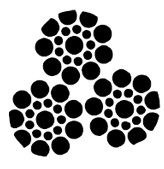

ROEPAC COMPACTED

Strands: 3

Wires per strand: 19/37/43

Core: None

Lay: Right Regular

Finish: Bright

ROEPAC is a three strand compacted rope with high breaking strength and stable construction making it perfect as a pulling rope for overhead transmission lines and underground conduits. It’s flexibility and flat surface provides snag-free guidance of the attached lines.

Abrasion Resistance. Compacted design provides improved abrasion resistance compared to standard 6 strand ropes because of the increased wire and strand surfaces contacting the sheaves and drum.

Resistance to drum crushing.

ROEPAC's compact design offers increased resistance to drum crushing.